Whether you’re taking on a new project or just working your way back into your shop or garage, selecting the proper tool for the job is of the utmost importance. When it comes to using saw blades, there truly is a precise science that goes into making sure you make the correct choice. We could discuss dozens of possible uses and scenarios but today we will focus on selecting the proper Table Saw Blade.

It is often that I hear our customers say “I will just buy a good General Purpose Saw Blade because I am on a budget”. This statement puts me in a bit of an awkward position. While I want everyone to have the right blade for their needs, I realize that quality tools can be costly at times. However, that does not mean you have to sacrifice quality for cost. If you are going to spend your hard earned money on one tool in the garage or shop, spend it on a quality saw blade.

Depending on the type of material you are working with (wood, plastic, metal), your saw blade selection can mean all the difference in the world. Even if you don’t have the best table saw money can buy, a good quality blade can make beautiful, straight and accurate cuts. Here are the important questions to ask when selecting the proper Table Saw Blade and their answers below:

- What is my desired output?

- What type of material will I be cutting?

- How long do I want my blade to last?

When selecting a table saw blade, the most important question to ask what your desired output should be.

If you’re looking to just “Rip” some material, or make fast inaccurate cuts, then your standard 10 inch carbide-tipped General Purpose Saw Blade will do the trick. General Purpose Blades typically feature a low tooth count, high hook angle and deep gullets to make them an aggressive, fast cutting solution. Don’t worry, we will explain these terms further down if you’re unfamiliar with them.

Not all General Purpose Saw Blades are made equally so make sure you do your homework. Amana Saw Blades have set the industry standard for the last couple of decades and quality is never a concern with any of their products. Amana Tool# 610300 is a great 30 tooth blade for “ripping” and “cross cutting” wood and the best part is it’s under a hundred dollars.

If you desire more accurate cuts and demand nothing less than perfection, continue on reading through the article to find more precise solutions to your needs…

Another important thing to consider is the type of material you will be cutting into.

Sure a General Purpose blade will cut just about any wood product, plastic or non-ferrous metal out there but the quality of the cut and the risks of associated with using a the wrong blade aren’t worth the time, aggravation and money you will end up wasting.

Selecting the proper blade to cut your material is paramount to the success of your project and the overall lifetime you get out of your blade. Let’s discuss a couple common scenarios most shops or Do-It-Yourselfers will face…

- Say you are building cabinets and working with a dual sided melamine (melamine on either side of the wood product). The most common mistake people make is “tearing out” the underside of the board by using the wrong type of saw blade. A “tear out” is when the melamine chips away from the board and leaves you with rough or splintered edge. This is also common when working with some veneers and plywood. As a woodworker, we demand nothing short of perfection. While “tear outs” aren’t common, they do occur but every one that does was avoidable.

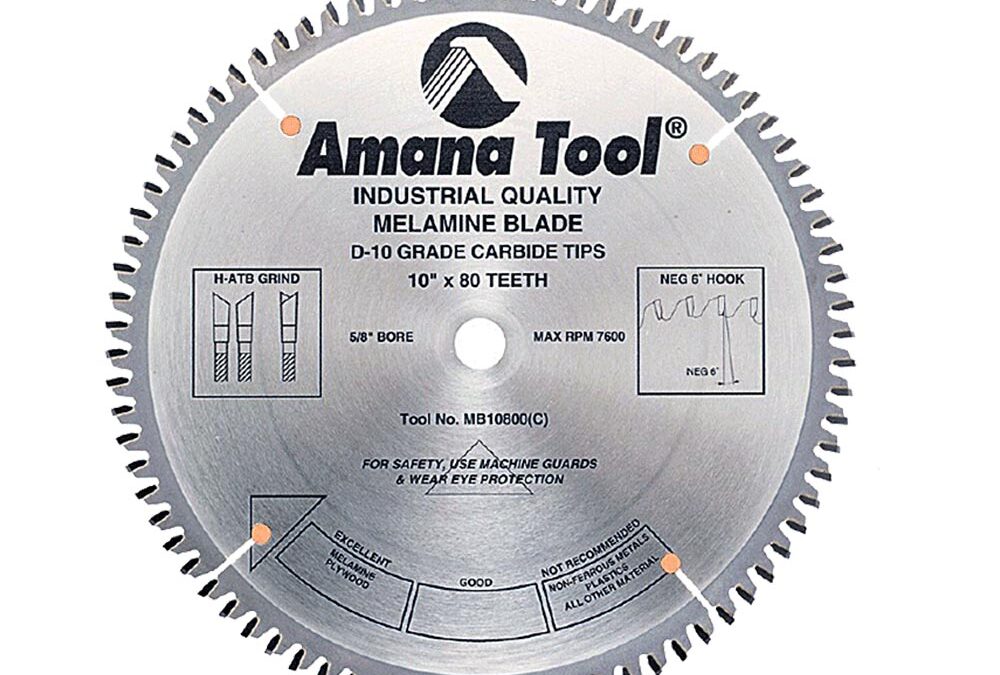

- Sticking with the industry leaders, Amana Tool# MB10800 is a Melamine and Laminate Saw Blade that can be found in almost every cabinet shop and many garages around the world. Not only are they the perfect blade for cutting melamine, but they totally eliminate chipping and splintering when cutting plastic laminate such as Formica and Wilsonart sheets, MDF (Medium Density Fiberboard), Plywood, Particle Board and other Chip Boards and even Non-Ferrous Metals. This eliminates the need for scoring the board before cutting into it.

- What if you are just cutting natural hardwoods like Oak, Maple or Mahogany? Or softwoods such as Pine, Birch or Ash? Well you can use that Amana 610300 or any General Purpose Blade to get the task completed. But that’s not going to provide you with that perfection you’re demanding will it? There are two types of blades you will need when cutting wood that have a grain.

Cross Cutting Saw Blades are used to cut across the grain and typically feature more teeth (between 60 – 96) to quickly and efficiently move wood fibers out of the way. This is why you would typically find blades such as these in any heavy-production cabinet shop. We use and recommend the Amana Tool# 610600 for cross cutting hardwoods and softwoods.

Ripping Saw Blades are used to cut along the grain and usually have less teeth (between 20 to 30) and deeper gullets for faster chip ejection. There are all sorts of Ripping Blades suited for various needs but rather than list them all off and the roles the fill, we will focus on Combination Ripping and Crosscut Saw Blades. These blades, such as the Amana Tool# 610504, typically have 50-60 teeth and they can rip or cut Plywood, Hardwood/Softwood and Chip Board.

There are a few other things to consider when purchasing or using the correct saw blade and some terms you will need to familiarize yourself with.

- Blade vibration or “resonance” can cause warping of the blade, chipping and splintering of material you’re cutting and may eventually damage your saw. If you have the option, use a blade equipped with a heavy duty plate for added stability and to reduce vibration. The previously mentioned Amana MB10800 is a great example of such a blade.

- If you are experiencing issues with vibration, check your table saw from time to time to ensure proper alignment. The blade and fence should be exactly parallel to the miter slot. If this doesn’t work, check to make sure the arbors and collars are clean. You should also check the drive belt for slippage. If you’ve followed these steps and still experience vibration problems, consider using a blade stabilizer to increase the overall stiffness of the blade.

- The biggest drawback to working with wood is it’s susceptibility to humidity. It is constantly changing shape and size as it absorbs the moisture in the air and determining the proper blade is crucial to having the finished product you desired. When working with Steel, Aluminum or other metals, ensure you blade is designed for that sort of application to prevent damage to you, your saw and your blade.

- The most important part of your table saw is the blade. You can probably get decent cuts on an average blade. However, choosing the correct blade for the right application, proper teeth per inch and proper tooth configuration or “Grind” will ensure you end up with the desired end result. Some common Grinds you will come across are listed below.

ATB – Alternate Top Bevel means the bevel on the teeth will alternate Left and Right for each tooth. These are commonly found on General Purpose, Combination and Crosscutting Saw Blades.

H-ATB – Higher Alternate Top Bevel has a higher grind and longer teeth for chip-free cutting of Melamine eliminating the need for scoring.

4+1 – Combination Tooth of four alternate top bevels and one flat ground tooth that are separated by large gullets. These are also found in combination and general purpose blades.

TCG – Triple Chip Grind has an alternating flat tooth and a higher, chamfered, corner less tooth that is most commonly used to cut hard materials, plastics and non-ferrous metal.

- Tooth Angles are also extremely important when selecting the proper saw blade. Below you will find some commonly used terms and their definitions.

- Hook or Rake Angle – This is the angle at which the saw tooth “leans”. Positive Hook Angle means the tooth leans forward to a degree. Higher angles are typically used on soft materials or for faster ripping.

- Lower angles are usually used on hard materials. Negative Angles mean the tooth “leans” backward and are almost always used for cutting materials that require a slower, less aggressive approach such as laminate, melamine and metal. This allows you to guide the material at a more controlled pace for a cleaner cut.

- Other common terms you will come across are “Kerf” represented by the letter “B” and this is quite simply the largest width of the saw tooth. “Plate” thickness on which the teeth are brazed represented by the letter “C”. These two are numerical values listed in both inches and millimeters. Finally, you will see the Diameter “D” which is the overall diameter of the blade and the Bore “d” and this refers to the diameter of the arbor hole or keyhole. The Bore and Diameter are also represented in inches and millimeters.

Well this concludes our brief discussion on selecting the proper Saw Blade. We hope this article can be used as an aide for those of you looking for some guidance. If you would like more information on this subject or if you would like to view some of the products discussed, please drop by our website at CabinetmakerWarehouse.

You may also reach one of our experts toll free at 1-866-322-3835 or by email at [email protected]